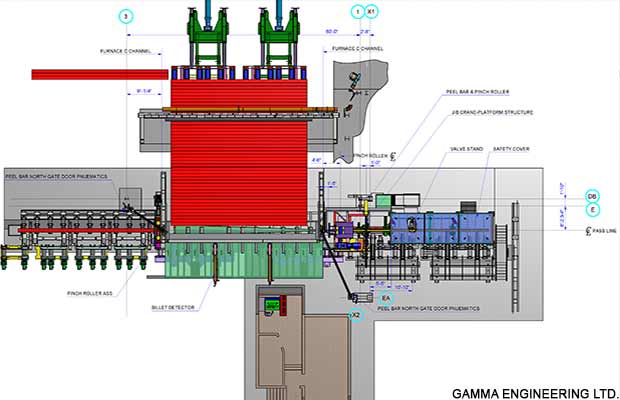

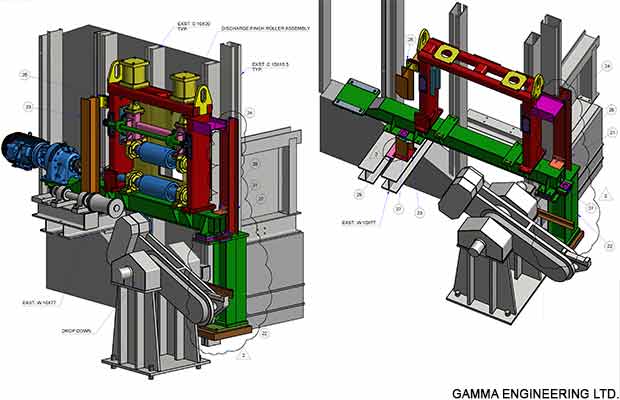

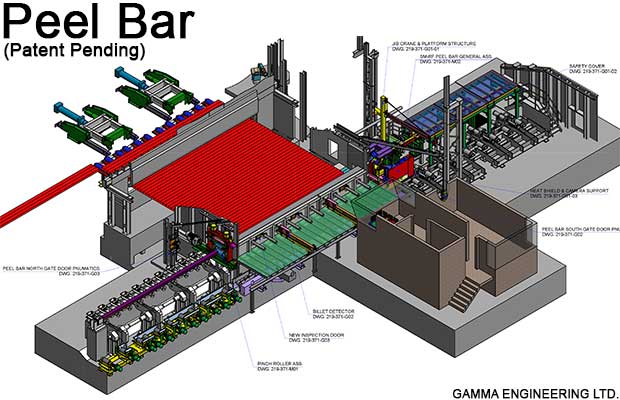

One of our client is planning to upgrade the current billet processing process by changing the machinery process required to bring billets out of the reheat furnace. The current procedure requires the use of a roller table that consists of 11 rollers with motors to operate. The roller table is located inside the furnace and is attached to 11 individual motors located outside the furnace that each rotates independently. Gamma Engineering Ltd. had designed a machine that will be cost effective and be a solution to some of the existing machine’s working issues.

The design of the “Peel Bar” machine closely address all the existing problems the roller table had. If billets were stuck together inside the reheat furnace, the peel bar would simply push and separate the two billets inside the furnace. The slipping of the roller table would not happen to the reheated billets since it is not being pushed and pulled instead of relying solely friction to pull the billets out. Energy consumption and maintenance cost is also greatly reduced by having few mechanical components within this system.